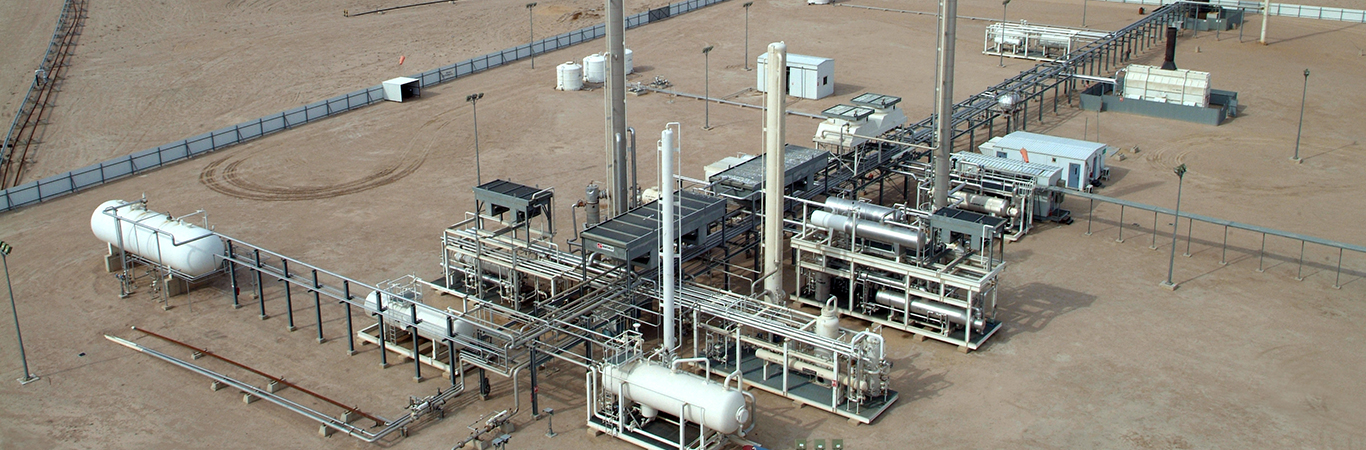

SPETCO specializes in handling of EPC & lease (BOO & BOOT) contracts for production systems and production facilities where we engineer, design, construct, commission, operate and maintain facilities for hydrocarbon processing requirements of our clients.

We consider progress to be an endless journey in pursuit of excellence. And value quality benchmarks as milestones. Our commitment to qualitative excellence has led to an ISO 9001, EN ISO 14001 & BS OHSAS 18001 accreditations.

As a corporate entity, everyone in the Group is geared to conform to exacting benchmarks to function in a world that is increasingly becoming quality conscious. And we keep setting our sights higher and higher in this pursuit that is relentless.

SPETCO's Specialty & Expertise in Sour Crude & Gas Processing:

· Early Production Facilities for Extended Testing of wells

· Amine Treating Units

· Crude Stabilization Units

· Gas Sweetening Facilities

· Sulfur Recovery Units

· Gas Compression Packages

· Gas Re-injection Packages

SPETCO's Proven Track record:

SPETCO has a track record of having successfully executed five major sour gas & condensate processing facilities projects in KOC on a BOO / EPC basis in the past decade and are currently executing the 50 MBOPD Jurassic Production Facility (JPF-4) in North Kuwait for KOC.

SPETCO International's contribution to the development of hydrocarbon reserves in Kuwait

The theory of an Early Production Facility in Kuwait was conceived to facilitate KOC to produce from the New Jurassic Reservoir.

Kuwait Oil Company (KOC) commissioned SPETCO to design, construct, commission, operate and maintain the Gas Processing Facility located in Western Kuwait.

The project is intended to increase the gas export capability and reduce the gas and condensate flaring in the Gathering Center 16 (GC-16), in line with the Kuwait Oil Company's objective of achieving zero flaring.